Engineering Services

Design Engineering

- Strategic Planning

- Development Path/Roadmap

- Critical Requirements Review

- Proof of Concept Validation

- Iterative Prototyping

- Manufacturing Readiness

- Failure Mode and Effects Analysis (FMEA)

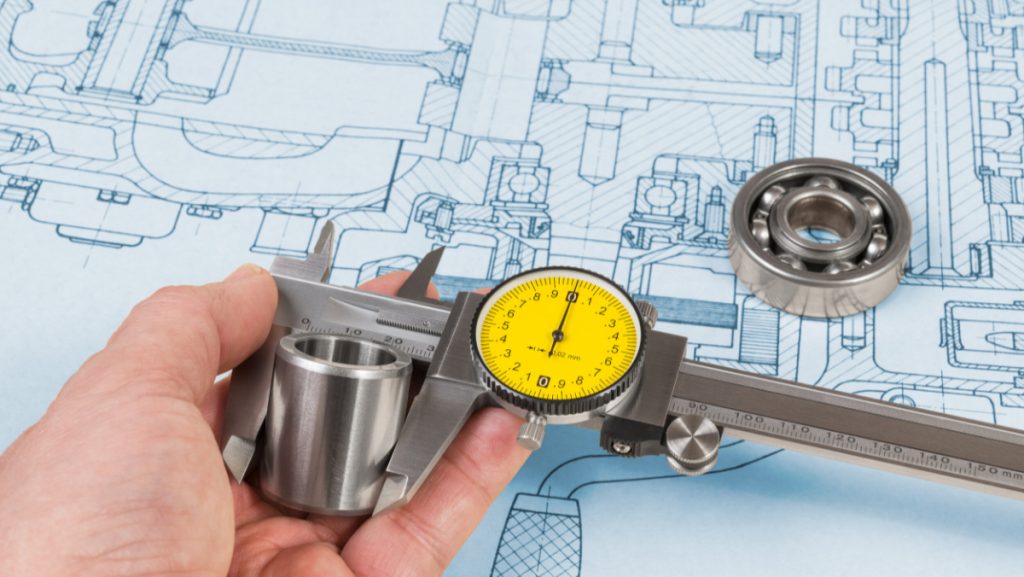

Tooling and Fixture Design

G3 has extensive experience designing:

- Tooling & Fixturing

- Composite Tooling

- Injection Mold Tooling

- Extrusion Dies

- Complex Surface Tool Design

Aircraft Interiors & Structures

We’ve successfully completed multiple on-site engagements supporting Tier-1 suppliers to Boeing and Airbus. G3’s engineers bridge the gap between OEM’s and Suppliers by preparing and submitting datasets directly into the client’s data management (PDM) systems.

In-Depth Understanding of:

- Digital Product Definition

- Model-Based Definition

- LOPA’s

- Master Definition Surfaces

- OEM Requirements Documentation

Military

Design and Tooling engineering:

- V-22

- Tow Missile

- Missile launch systems

- Satellite

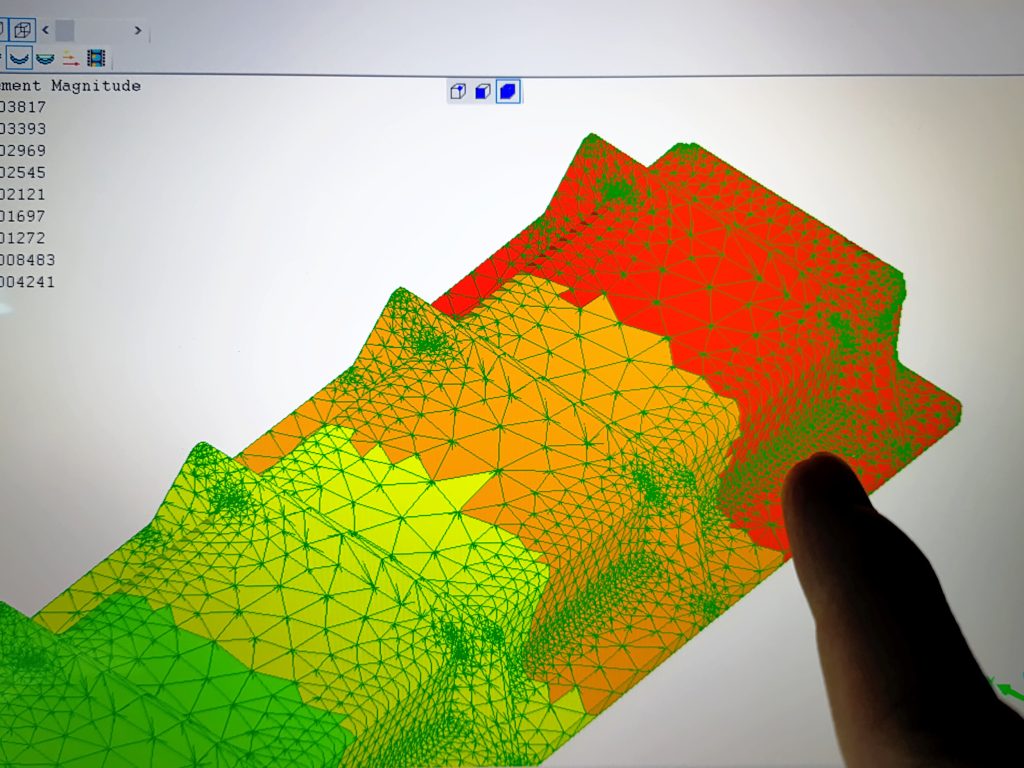

Analysis & Simulation

Finite Element Analysis (FEA)

- Full simulation & stress analysis

- Product design and structure performance optimization

- Nonlinear contact, thermal analysis, dynamic analysis, fatigue analysis, etc.

- Composite, rubber, plastic, metal parts and assemblies

Computational Fluid Dynamic (CFD)

- All types of CFD consulting

- Steady, Transient, Incompressible, and Compressible flows

- Fluid-structure interaction, non-linear structural materials

- Heat Transfers (Convection, Conduction, and Radiation)

Industrialization Planning

G3’s industrialization department is made up of multi-disciplinary teams of manufacturing engineers, fixture designers, and CNC programmers.

We ensure a seamless link between the customers’ requirements and engineering/production readiness in developing processes that deliver consistent quality/optimized cost-effectiveness.